STANDARD EQUIPMENT

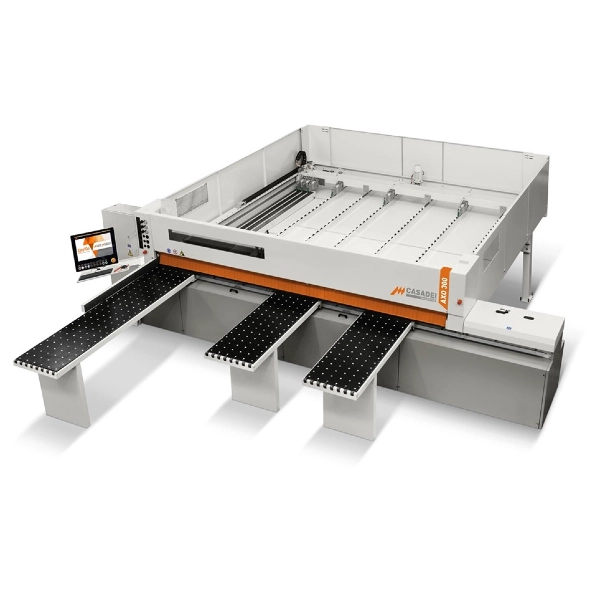

Machine Frame

– Sturdy machine frame in tubular steel.

Automatic star-delta-starter for main blade

– Rear part made in extruded aluminium, with wheels made of anti-scratch material and a 400 mm wide full table with phenolic covering, positioned on cross-cutting fence side.

– Heavy plate steel table with double tubular structure in ribbed steel and with phenolic covering.

– Safety protections around the machine.

Saw Carriage

Steel saw carriage

– Independent motors for main blade and for scoring blade

Automatic star/delta starter for main blade

– Vertical rise & fall over prismatic guides and ball-runner blocks.

– Saw carriage slides over two steel tempered and rectified cylindrical guides protected by special dust scrapers.

– Saw carriage feed by rack and pinion.

Saw blade and scoring blade flanges with pneumatic locking

– Perfect cutting finish guaranteed by mass balancing.

– Hardened and rectified prismatic steel wheels.

– Scoring unit axial and vertical micrometric adjustment from outside.

– Saw carriage stroke against cross-cutting fence.

– Cross-cutting fence placed on the left side.

– Slotted pressure beam. The panels are always gripped up to the last cut. Vertical pneumatic movement with precision rack & pinion system, adjustable pressure 1,5 – 6 bar.

– Double dust collection system: top dust collection system on the pressure beam to keep worktable clean and lower dust collection system on the saw carriage.

– Overhead control panel on the left side.

Control

Control and programming system Includes

Console with integrated PC Smart Control equipped with:

(minimum features):

– Industrial PC “fanless.

– Protection class IP53 (only on front IP65).

– LCD colour display: 21,5”, Full HD; 16/9; LED backlighting; 10 touches capacitive multi touch screen; viewing angle 176°H, 160°V “zero pixel defect”.

– Intel Pentium processor; 2,9 GHz.

– RAM memory: 8 GB.

– Hard disk: 256 GB.

– Operating system: Windows.

– Qwerty keyboard with English layout.

– Wired mouse.

– Ethernet socket RJ45.

– Single, external USB port. 3.0.

– Nominal operating temperature: from +5°C to +35°C .

– Software Easy2Go Cut.

Easy2Go Cut with following functions:

Working modes

– Manual mode for axis movements.

– Automatic mode: execution of cutting programs and/or lists of cutting programs.

– Semi-automatic mode: execution of different measures programmable from the keyboard.

Advanced Editor of cutting pattern

– Advanced editing system for cutting pattern in WYSIWYG mode for management of longitudinal, transversal cuts, pre-cuts, trim cuts and second level cuts.

Advanced file browsing system

– The file browser Easy2Go cut allows t0 manage/start/copy/delete the machine programs. A real-time preview function allows to check in browser each cutting pattern.

Control Paddle (screen)

– Virtual pushbutton control panel.

Management of tools and materials archives

– The materials and tools archives allow to archive each item with its operating and execution parameters.

Machine simulator

– Possibility to view the graphical simulation in real time with indication of the cutting dimensions and timing.

Reporting system

– The control records every single action/event in the machine and makes available production reports, events, alarms and maintenance.

Maintenance support

– Easy2Go cut reports operations to be carried out on the machine, with periodic notifications connecting them to the relevant procedure.

Diagnostic system

– Easy2go Cut detects and displays alarms and warnings, offering help for elimination of the current error.

User management

– Easy2Go records the activities of each operator registered in the system.

Label editor

– The label editor allows creation and printing of labels even with bar codes directly on the machine. The operator can enter new data on the label or

transfer them from the Perfect Optimiser Plus or Easy Cut Pattern Optimiser database. Information can be printed with a text or bar codes. In addition, it is possible to add imagines or lines.

Additional functionalities included in specific modules make Easy2go Cut extremely flexible for pieces labelling, with the possibility of previews

during editing and execution pattern, enabling elaboration of statistical information even more detailed.

Measuring system

– Measuring unit: millimetres-tenths or inches-thousandths.

Available languages

– Operator’s interface available in the following languages: Italian, English, French, Spanish German.

Note: The description of the control system includes certain functions that are present only with a suitable machine mechanical or electrical set up. As a result, the label data editor in each program is present only with the relative optional devices, shown in the price list, selected on the machine.

Easy Cut Pattern Optimiser

cutting optimiser Optimization software for creating cutting programs starting from the raw panel up to the finished panel. Easy Cut Pattern Optimiser processes the layout of optimized cutting pat-terns, which are automatically converted to cutting programs without the intervention of the operator. At the end of optimization, the cutting pro-gram related to the layout created by Easy Cut Pattern Optimiser is auto-matically saved in the directory of the program Easy2go Cut, the software for cutting management. The program manages a small panel stock.

Technical features:

– Types of formats for each material: 5.

– Max. no. of lines per program: 30.

– Max. no. of pieces per line: 500.

– Cutting level: longitudinal (Y), transversal (X) third level (Z).

– Management pre-cut.

– Management off-cuts stock interfaced with Easy2Go Cut.

– Statistic report: % order waste, number of used panels, number of produced panels.

– Graphic visualisation of product schemes .

– 8 import fields for label information (material, type of colour, thickness, width, length, code, description, 4 edges fields).

– Panel stock: 2.

– Import from XLS file >= Excel 97. Allows import of Excel files with data related to the pieces of a cutting list of only one material (code, description, length, width, quantity, grain, 4 edge fields).

Teleservice

system service via internet The remote diagnosis system allows you to connect your PC with the ser-vice centre via Internet

Software: linking program for:

– Upgrade the machine logic and operatorinterface.

– Back-up data and file transfer.

– Control configurations, parameters and programs.

– Interface and display diagnostic signals.

Note: Network cable and PC not included. The Internet connection must be prepared by the customer.

Service free of charge for the duration of the warranty.

Side aligner

Single side aligner with automatic positioning

with pneumatic cylinder 1200 mm stroke:

– Minimum width: 60 mm.

– Maximum width: 1200 mm.

– The side aligner slides over a THK prismatic guide and ball runner blocks.

Pusher

Full length powered pusher

with central drive system and two heavy duty torsion bars.

Electronically adjustable pusher positioning by means of a magnetic strip (contactless system).

The pusher travels over two sturdy “H” beams.

Pusher feed is achieved by two high precision pinions to ensure that the pusher and the cutting line are always perfectly parallel over the full stroke of the pusher. The pusher is driven by brushless motor to offer constant torque at any speed, stepless speed adjustment up to 0 and high perfor-mance without need of maintenance.

– 5 clamps for panels clamping.

– Adjustable locking pressure of the clamps.

– Pair of saw blades.

Electrical equipment

Electrical system with high safety features, complete with:

– Dust-proof cabinet (IP 55).

– Padlock able main switch.

– Control voltage 110 Volts for control board, electronic control and low voltage signals.

– Overload switches for the motors.

– Saw blade access door electrically interlocked by safety micro-switch.

Rotating front safety guards to cover cutting area.

Emergency safety bar on the entire cut line.