Space Saving Solution for Ease of Installation

Restrictive regulations and market requirements such as oversized fuel tanks and large vehicle exhaust modules continue to create space constraints on truck chassis rails for mounting traditional belt driven compressors. The CS1200 ICL tackles this common industry challenge by providing a plug and play, truck mounted solution. A narrow footprint results in a compressor package that can be bolted directly onto most European manufacturer’s 4×2, 6×2, and 6×4 chassis rails, without the need and expense of additional fabrication.

Temperature Controlled Discharge

Controlled cool air ensures that heat sensitive products can be discharged without fear of degradation. The GHH RAND temperature controlled CS1200 ICL delivers peace of mind with discharged air temperature reduced to as low as 50 degrees, protecting your product.

Enhanced Product Safety with Patented Technology

Additional safety of your discharged product is ensured with GHH RAND oil free compression. This is achieved thanks to a unique patented sealing system which ensures absolutely no oil contamination of the discharge air.

Food Grade Rotor Coating & SILOL® FG Lubrication

Corrosion free rotors protect your product from contamination and provide peace of mind on restart after standing. This, combined with our SILOL® FG lubricant, provides you with a hygienic solution specifically designed for the bulk discharge of food and other temperature sensitive products.

Vehicle Specific Mounting Frames

GHH RAND offer a variety of vehicle specific, fully engineered & FEA-calculated steel brackets for safety and longevity in harsh road conditions.

German Engineered Performance Optimised Airend

Our airends feature a performance optimised geometry that has been engineered specifically to guarantee the perfect fit in the close confines experienced when mounting under and within the chassis rails.

Optimised Propshaft Angle for Reduced Maintenance

The input shaft is located at the back uppermost of the airend which increases the length of the prop shaft and thus decreases the angle. This enables a better engineered solution that ensures compliance with maximum limits of compound angles, resulting in a longer life expectancy and increased uptime.

Close Coupled Reactive Discharge Silencer Fitted Directly onto Airend

We offer an integrated, geometrically optimised, non-migrating media discharge silencer that can bolts directly onto the airend to maximise spacesaving and ensure everything fits securely inside the chassis, eliminating the need for additional supporting bracketry.

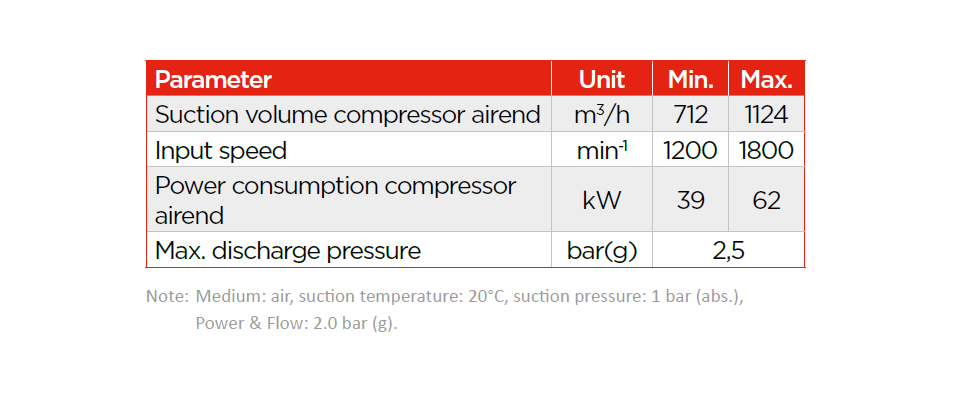

2.5bar Gauge

Our compressors offer 2.5 bar gauge operation across a wide speed and flow range, enabling discharge of problematic products into challenging applications.